If you need to print labels for your products, it’s best to understand the printing process before you order your labels. Let’s look at the different types of label printing and their processes. From there, you can determine which type of printing fits your labeling needs.

The Basics of Three Label Printing Types

US Tape & Label offers three main types of label printing: digital label printing, flexographic printing, and rotary screen printing. Here are the basics of these printing types:

- Digital Printing: In digital printing, an electronic file converts a digital image into a series of dots called a bitmap or raster image. The bitmap guides the printer’s imaging device to where it should put the ink and toner to create a label. Unlike other types of label printers, digital printers don’t use metal plates to create their images. Digital printing allows for smaller batches of labels than other printing types. You can also use digital printing to create variable images, where each label has a slightly different barcode or set of numbers on it. Digitally printed labels appear in high resolution on a wide range of paper and film materials.

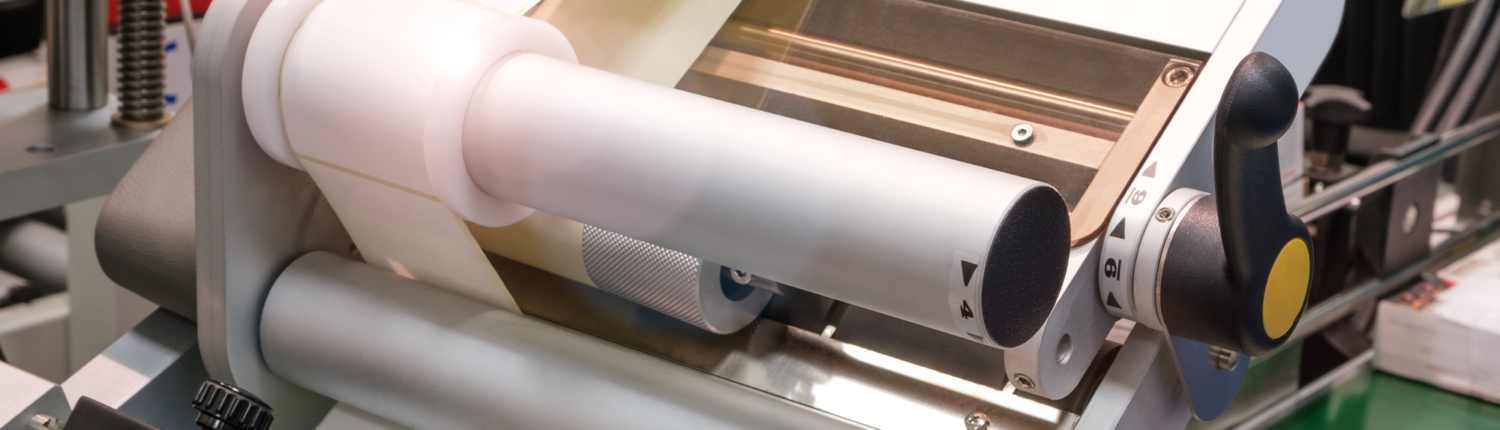

- Flexographic Printing: The flexographic printing process sends labels through a series of rotary plates. A specialized roller delivered one color to each plate at the beginning of the printing process, and all the plates work together to deliver the different colors to each label. The flexographic process integrates seamlessly with additional printing steps, such as die-cutting and laminating. Flexographic labels often appear on non-porous materials, including plastic, foil, brown paper, and food service paper. They also work extremely well on shrink-sleeve packaging.

- Rotary Screen Printing: Rotary screen printing has been used since the 1800s, though the technology used in its printing process has evolved significantly since then. When you create labels with rotary screen printing, the printer pushes ink through perforated mesh holes. This printing process adapts to a wide variety of materials and inks, and it creates textured labels with heightened visual and tactile appeal. You can use rotary screen printing to create Braille lettering that makes your labels more inclusive.

Reach out to us to choose the right type of printing for your products labels and start the printing process.

Label Design Tips for Your Products

Here are some tips for creating high-quality labels during the label design and printing processes:

- Consider what your buyers like: Think about the demographics you want to reach with your product packaging. Research what these demographics like and dislike about your type of products’ labels and packaging.

- Create a design that fits your brand: After you consider and research your demographic, it’s time to make an eye-catching design that appeals to them. If you employ a graphic designer, ask them to create mockups of potential designs. The designs should fit your business’s brand and reflect the image you want to project to customers.

- Contact US Tape & Label: Once you have chosen your label design, reach out to us to begin the printing process. We help you choose the right printing process for your labels. We also help you select a design template, such as a die-cut, shrink sleeve, or specialty shape template.

Why Partner With US Tape & Label?

US Tape & Label has produced high-quality labels for businesses nationwide since 1950. We’ve updated our equipment and processes over the years to integrate the latest printing technology into our service offerings. We serve a wide range of industries with our label printing services, from food to automotive to cannabis to lawn and garden. We customize our printing services to meet your labeling needs while offering the highest available printing quality for your label and packaging designs.

Print Your Product Labels With US Tape & Label

If you have a label design you want us to print, reach out to us today. We collaborate with you to use the correct printing process for your product’s label and packaging needs. Our processes fit a wide variety of printing materials. Whether you need labels printed on paper, film, or foil, we have you covered with our services. Partner with us to create eye-catching labels that draw your customers in and entice them to buy your product. We’re ready to print your labels as soon as you reach out to us.

Get In Touch

Phone

(314) 824-4444

Why U.S. Tape & Label?

Centrally-located and equipped with the cutting-edge equipment you need to get the best labels and look for your products. Our skilled team of in-house engineers will help you make the perfect label for any product you have.