https://ustl.com/wp-content/uploads/2025/11/Pressure-Sensitive-Labels.jpg

1250

2000

AbstraktMarketing

https://ustl.com/wp-content/uploads/2025/06/USTL-Logo-2025-Anniversary-LargerBanner.png

AbstraktMarketing2025-11-10 22:27:452025-12-25 14:32:35Comparing Shrink Sleeve and Pressure-Sensitive Labels: Which Is Better for Your Food Label?

https://ustl.com/wp-content/uploads/2025/11/Pressure-Sensitive-Labels.jpg

1250

2000

AbstraktMarketing

https://ustl.com/wp-content/uploads/2025/06/USTL-Logo-2025-Anniversary-LargerBanner.png

AbstraktMarketing2025-11-10 22:27:452025-12-25 14:32:35Comparing Shrink Sleeve and Pressure-Sensitive Labels: Which Is Better for Your Food Label?How To Select and Purchase the Ideal Labeling Equipment for Your Business

Labeling may seem like a small step in your production line, but it’s often where a product goes from “unfinished” to “ready for the shelf.” Choosing the wrong labeling equipment can slow your operations, increase costs, and damage your product’s appearance. On the other hand, the right equipment keeps everything running smoothly, helping your labels look flawless, stay secure, and meet your production deadlines without unnecessary hassle.

We’ve seen how a well-thought-out equipment choice transforms a labeling process. With over 75 years of experience supporting businesses across industries, we know what works, what doesn’t, and how to help companies find equipment built to last. This guide walks you through the most critical factors to consider when selecting labeling equipment for your operation.

Understand Your Label Type and Product Shape

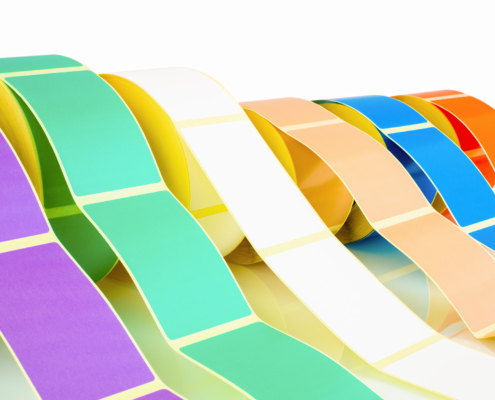

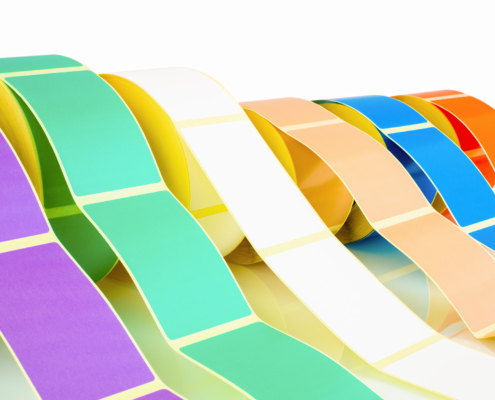

Before diving into specs or brands, start with the basics: What type of labels will you be using, and what kind of containers are you labeling? A round glass bottle needs a solution different from a square carton or a flexible pouch.

Common label types include:

- Pressure-sensitive labels: Popular and versatile, these can be applied to a variety of surfaces with precision.

- Shrink sleeve labels: Ideal for full-coverage branding and unique container shapes.

- Glue-applied labels: Common in high-speed beverage bottling lines.

- Embossed or specialty finishes: Often require specialized application processes to ensure they adhere perfectly.

By knowing your label type and container shape, you’ll narrow down your labeling equipment options significantly.

Label Printing Considerations

Even the best labeling machine won’t perform if your labels aren’t compatible with its requirements. This is where label printing and application go hand-in-hand.

Key label printing considerations:

- Material: Paper, film, or foil labels interact differently with adhesives and application methods.

- Finish: Matte or gloss coatings may require adjustments to the equipment’s roller pressure or sensor calibration.

- Specialty size and shape: Irregular labels pose challenges unless the equipment is made to handle them.

Match Equipment to Your Production Volume

Production volume is another key factor. A small-batch artisanal brand has very different label printing needs than a large-scale food processor.

- Low-volume production: Semi-automatic machines are often enough for smaller runs or start-ups testing their products.

- Mid- to high-volume production: Fully automated systems with conveyor integration are better suited for large batches, reducing labor and speeding up the application process.

We often advise businesses to think long-term. If your company is growing fast, investing in scalable labeling equipment now can prevent costly upgrades later.

Think About Automation and Integration

Modern labeling equipment ranges from simple tabletop units to fully automated inline systems. The right choice depends on:

- Current line setup: Does your equipment need to integrate with fillers, cappers, or shrink tunnels?

- Staffing: A more automated solution can reduce labor costs if your team is small.

- Precision needs: Automated machines offer consistent placement and speed, reducing errors common with manual application.

We often recommend evaluating how much time you’re currently spending on labeling products. For many growing businesses, upgrading to automated labeling equipment pays for itself within months due to efficiency gains and reduced waste.

Factoring Space Constraints and Layout

Where will your new machine fit? Labeling equipment varies in footprint, and cramming an extensive system into a small space can create workflow bottlenecks. Measure your production area carefully and think about how the equipment will align with your other machinery.

Compact labeling systems are available, but should still offer enough functionality to meet your needs. We’ve seen businesses overcompensate by choosing the smallest equipment possible, only to outgrow it within a year.

Common Types of Labeling Equipment

To give you a clearer idea of what’s out there, here are some popular options:

- Wrap-around labelers: For cylindrical containers like bottles and jars.

- Front-and-back labelers: Apply labels to flat or oval containers with precision.

- Top or bottom labelers: Ideal for trays, lids, and boxes.

- Shrink sleeve applicators: For products that require 360-degree label coverage.

- Print-and-apply labelers: Combine label printing with on-the-spot application, perfect for logistics or variable data.

Choosing between these often comes down to your product type, speed requirements, and labeling budget.

At U.S. Tape & Label, we provide durable, high-quality labels and the labeling equipment capable of matching production to performance. Find the label printing equipment you need to increase efficiency and avoid misalignment or waste.

Considering New vs. Refurbished Equipment

Another consideration is whether to invest in new or refurbished equipment. New machines offer the latest technology, full warranties, and lower maintenance needs, while refurbished units provide upfront cost savings but may require more frequent servicing.

Many businesses have succeeded with refurbished labeling equipment, especially when starting out. However, new machines often deliver better reliability and fewer compatibility issues with advanced label solutions.

When to Consult a Labeling Specialist

Purchasing labeling equipment isn’t just about buying a machine; it’s about choosing a long-term partner to support your production goals. A specialist can evaluate your products, production line, and budget to recommend the best solution.

U.S. Tape & Label (USTL) takes pride in guiding businesses through this process. With decades of experience across industries like food, beverage, pharmaceuticals, and consumer goods, we’ve helped countless companies select equipment that aligns with their current needs and future growth plans. Our offerings include equipment, replacement parts, and expert support to keep your operations running efficiently.

Take the Guesswork Out of Your Labeling Equipment Purchase With USTL’s Support

Selecting the right labeling equipment and accessories is an investment that impacts everything from efficiency and cost control to how your product looks on the shelf. By considering factors like label type, volume, automation, and integration, you’ll be well on your way to making a wise, future-proof choice.

As an authorized dealer of Label-Aire, CTM Labeling Systems, and Pack Leader, we can help you find the equipment to take your labeling process to the next level. Contact U.S. Tape & Label today to discuss your production goals, explore equipment options, and discover why our expertise makes all the difference in achieving reliable, high-quality results.

Share This Post

More Like This

https://ustl.com/wp-content/uploads/2025/11/Pressure-Sensitive-Labels.jpg

1250

2000

AbstraktMarketing

https://ustl.com/wp-content/uploads/2025/06/USTL-Logo-2025-Anniversary-LargerBanner.png

AbstraktMarketing2025-11-10 22:27:452025-12-25 14:32:35Comparing Shrink Sleeve and Pressure-Sensitive Labels: Which Is Better for Your Food Label?

https://ustl.com/wp-content/uploads/2025/11/Pressure-Sensitive-Labels.jpg

1250

2000

AbstraktMarketing

https://ustl.com/wp-content/uploads/2025/06/USTL-Logo-2025-Anniversary-LargerBanner.png

AbstraktMarketing2025-11-10 22:27:452025-12-25 14:32:35Comparing Shrink Sleeve and Pressure-Sensitive Labels: Which Is Better for Your Food Label? https://ustl.com/wp-content/uploads/2024/12/How-to-Create-Custom-Food-Labels-That-Stand-Out-on-Shelves.jpg

1250

2000

AbstraktMarketing

https://ustl.com/wp-content/uploads/2025/06/USTL-Logo-2025-Anniversary-LargerBanner.png

AbstraktMarketing2024-12-19 08:56:362025-12-25 14:32:39How to Create Custom Food Labels That Stand Out on Shelves

https://ustl.com/wp-content/uploads/2024/12/How-to-Create-Custom-Food-Labels-That-Stand-Out-on-Shelves.jpg

1250

2000

AbstraktMarketing

https://ustl.com/wp-content/uploads/2025/06/USTL-Logo-2025-Anniversary-LargerBanner.png

AbstraktMarketing2024-12-19 08:56:362025-12-25 14:32:39How to Create Custom Food Labels That Stand Out on Shelves https://ustl.com/wp-content/uploads/2023/03/Image-of-a-person-at-a-grocery-store-reading-a-food-label..jpg

1250

2000

AbstraktMarketing

https://ustl.com/wp-content/uploads/2025/06/USTL-Logo-2025-Anniversary-LargerBanner.png

AbstraktMarketing2023-03-21 09:00:002025-12-25 14:32:50Breakdown of a Food Label

https://ustl.com/wp-content/uploads/2023/03/Image-of-a-person-at-a-grocery-store-reading-a-food-label..jpg

1250

2000

AbstraktMarketing

https://ustl.com/wp-content/uploads/2025/06/USTL-Logo-2025-Anniversary-LargerBanner.png

AbstraktMarketing2023-03-21 09:00:002025-12-25 14:32:50Breakdown of a Food LabelGet In Touch

Phone

(314) 824-4444

Why U.S. Tape & Label?

Centrally-located and equipped with the cutting-edge equipment you need to get the best labels and look for your products. Our skilled team of in-house engineers will help you make the perfect label for any product you have.