https://ustl.com/wp-content/uploads/2025/11/Pressure-Sensitive-Labels.jpg

1250

2000

AbstraktMarketing

https://ustl.com/wp-content/uploads/2025/06/USTL-Logo-2025-Anniversary-LargerBanner.png

AbstraktMarketing2025-11-10 22:27:452025-12-31 14:27:43Comparing Shrink Sleeve and Pressure-Sensitive Labels: Which Is Better for Your Food Label?

https://ustl.com/wp-content/uploads/2025/11/Pressure-Sensitive-Labels.jpg

1250

2000

AbstraktMarketing

https://ustl.com/wp-content/uploads/2025/06/USTL-Logo-2025-Anniversary-LargerBanner.png

AbstraktMarketing2025-11-10 22:27:452025-12-31 14:27:43Comparing Shrink Sleeve and Pressure-Sensitive Labels: Which Is Better for Your Food Label?Everything You Need To Know About Embossed Labels

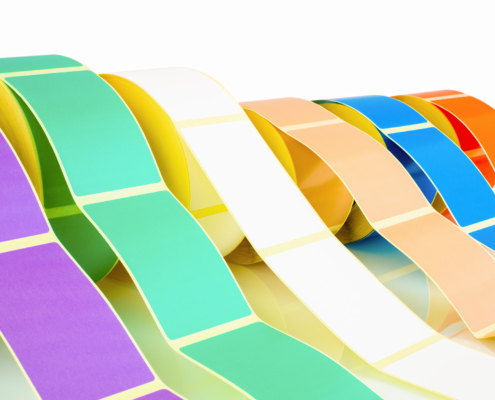

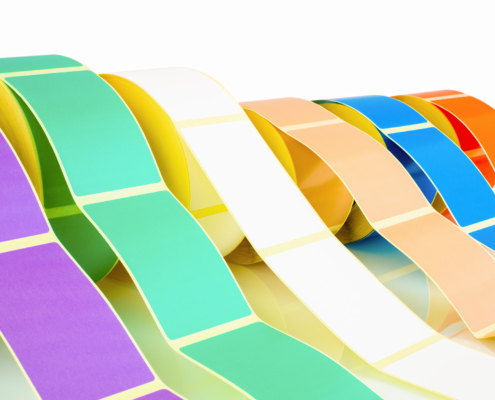

Whether you’re looking for a way to differentiate your products from the competition or add a touch of luxury to your packaging, embossed labels are an excellent option. They have a unique 3D effect that makes them stand out from traditional printed labelsand provides an extra layer of quality assurance for customers. In this article, we’ll discuss embossed labels, how they work, and why they’re so effective. We’ll also walk through the embossing process and the benefits of these labels. Let’s dive in!

What Are Embossed Labels?

Embossed labels are printed labels that feature a raised, textured pattern or design. This 3D effect is created by pressing paper between reversed type and a metal plate, pushing the material to create depth. The results are striking and immediately recognizable, making embossed labels an ideal way to add value to your products.

How Do Embossed Label Printers Work?

Embossed label printers use a combination of heat, pressure, and time to achieve the embossing effect. The materials used in embossing are heated before being pressed between the two plates. As the material cools, it takes on the shape of the type and creates an impression on the paper. Depending on your desired result, you may need to adjust the temperature or pressure settings.

Why Embossed Label Makers Are Effective

Embossed labels have several advantages over traditional printed labels:

- They give your product an extra layer of quality assurance with their unique 3D effect that stands out from other packaging options.

- They provide more exact details than standard printing techniques because of their precise heat and pressure application process, which ensures a clean finish.

- They can be used for small and large batches, meaning they’re perfect for companies looking for cost-effective labeling solutions.

The Embossing Process

Here is a step-by-step process for embossing printing:

- Design the artwork: When creating an embossed label, the first step is to decide on your design. You’ll need to consider the type of font you want, the graphics you’d like to include, and any additional text or images. It’s a good idea to create a few different concepts so that you can pick the one that best fits your product.

- Choose the paper stock: Select the paper or material you want to use for embossed printing. Thicker and heavier papers work better for embossing than lighter-weight papers.

- Create a die: A die is a metal plate with your design or text carved into it. The die is what creates the raised effect on the paper. You can create a custom die using a CNC machine, laser cutting, or etching.

- Mount the die: Once the die is created, mount it onto an embossing press. The press applies pressure to the paper, forcing it to conform to the shape of the die and creating the raised effect.

- Prepare the paper: Place the paper onto the press and align it with the die. You can use a registration mark or guide to position the paper correctly.

- Inspection: A visual inspection is the final step in producing quality embossed labels. Take some time to review each piece carefully and ensure all of the details are correct, and confirm there are no blemishes or mistakes in the final product. If any corrections are needed, they should be made at this stage before any additional processing takes place.

Note: Working with a reputable provider like U.S. Tape & Label is an excellent solution for outsourcing the entire process. You can receive the best quality embedded labels in the industry!

Are you interested in acquiring quality labelsfor your product packaging? Be sure your team understands everything about label printing before considering options.

Signs That Your Operation Needs Embossed Labels

- Labels need to be durable and long-lasting.

- Labels need to stand out and be easily identifiable.

- Labels must be readable by touch, particularly for individuals with visual impairments.

- Labels must resist wear and tear, including exposure to water, chemicals, and UV rays.

- Labels need to be tamper-evident, such as for security or warranty purposes.

- Labels need to be applied to irregular or curved surfaces.

- Labels must be used in environments where traditional labels, such as extreme temperatures or rough surfaces, may not adhere properly.

- For branding or product packaging purposes, labels need to convey a sense of quality or luxury.

The Benefits of Embossed Labels

Embossed labels are an excellent choice for businesses and individuals who want to make their products stand out. These labels provide a unique, three-dimensional effect that gives products a professional and high-quality look. Let’s run through a few benefits:

Enhanced Aesthetics

Looking for an enhanced aesthetic look to your product? The raised letters, logos, or images on the label create a 3D effect that looks attractive and makes the product stand out. Embossed labels also add a touch of elegance and sophistication to your products.

Durable and Long-Lasting

Embossed labels are incredibly durable and long-lasting, making them perfect for labeling products that withstand harsh environments, such as outdoor equipment or industrial products. These labels resist fading, abrasion, and damage from chemicals or extreme temperatures, ensuring they will last for years without needing replacement.

Tactile Experience

The raised letters and images on the label create a texture that can be felt, making the label more engaging and interactive. This feature can be handy for products aimed at children, where a tactile experience can add to the product’s appeal.

Branding and Marketing Benefits

The 3D effect and texture of the label help to make the product stand out on the shelf, increasing visibility and attracting potential customers. The raised letters and images can reinforce brand identity and help build brand recognition.

Customizable

Embossed labels are fully customizable, allowing you to choose the font, design, and color scheme that best suits your product or brand. This customization allows you to create a unique label tailored to your specific needs, ensuring your product stands out and is easily recognizable.

USTL: The Top Label Printing Company for Embossed Labels

Do you have a unique label design? At USTL, we’ll work together to determine the best printing method for your product’s labeling and packaging requirements. Our techniques can be adapted to various materials, such as paper, film, or foil. Contact us today for the best embossed labels in the industry.

Share This Post

More Like This

https://ustl.com/wp-content/uploads/2025/11/Pressure-Sensitive-Labels.jpg

1250

2000

AbstraktMarketing

https://ustl.com/wp-content/uploads/2025/06/USTL-Logo-2025-Anniversary-LargerBanner.png

AbstraktMarketing2025-11-10 22:27:452025-12-31 14:27:43Comparing Shrink Sleeve and Pressure-Sensitive Labels: Which Is Better for Your Food Label?

https://ustl.com/wp-content/uploads/2025/11/Pressure-Sensitive-Labels.jpg

1250

2000

AbstraktMarketing

https://ustl.com/wp-content/uploads/2025/06/USTL-Logo-2025-Anniversary-LargerBanner.png

AbstraktMarketing2025-11-10 22:27:452025-12-31 14:27:43Comparing Shrink Sleeve and Pressure-Sensitive Labels: Which Is Better for Your Food Label?

How To Select and Purchase the Ideal Labeling Equipment for Your Business

How Custom Die-Cut Labels Benefit Your Products and Packaging

The Psychology of Marketing Colors: How Product Labels Influence Buying Behavior

The Impact of Product Labeling on Consumer Purchasing Decisions

The Importance of Quality Automotive Labels and Proper Application

How to Create Custom Food Labels That Stand Out on Shelves

The Benefits of Creating A Custom Product Label

Why Use Custom Label Printing Services?

Get In Touch

Phone

(314) 824-4444

Why U.S. Tape & Label?

Centrally-located and equipped with the cutting-edge equipment you need to get the best labels and look for your products. Our skilled team of in-house engineers will help you make the perfect label for any product you have.